INTENSIFYING SCREEN

1) DEFINTIONS:

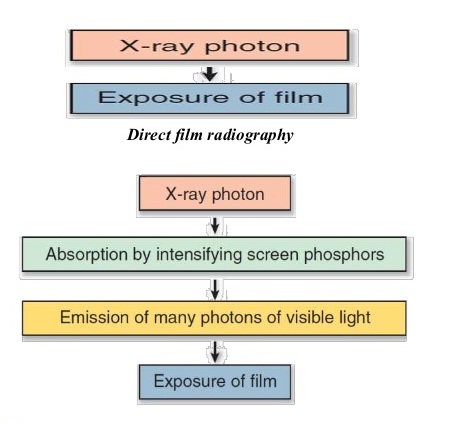

It is a device that transfers X-ray energy into visible light; the visible light, in turn exposes the screen film.

- These screens intensify the effect of X-rays on the film, thus less radiation required to expose a screen film, thus less radiation exposure to patient

- Action of radiation on photographic film is supplemented by means of special screens which intensify the action of X-rays

- An intensifying screen is a smooth plastic sheet coated with minute fluorescent crystals known as phosphors.